General Manager

Sven-Olaf Klüe has been working in the field of design, manufacture and applications of pillow plate heat exchangers worldwide for 27 years. For the past 15 years, he has focused specifically on the process-related applications of pillow plate heat exchangers in industrial applications.

Fish cooling

Chip Ice quality and economic efficiency of our BUCO industrial ice maker confirmed in test series of a fish processing company

When choosing between flake ice (1mm thick and temperature -8°C to -10°C) and our BUCO crushed ice (chip ice 6mm to 8mm thick and temperature -0.5°C to -1°C), there are often subjective visual preferences on the part of users in the field of industrial refrigeration to cool fish. Customers usually prefer flake ice because it looks visually colder (whiter) and is therefore considered to be better and more effective ice. This is not the case. Ice develops its greatest heat transfer effect when it melts (0°C) and thus at 335 KJ/kg (80 kcal/kg). In addition, ice near 0°C is the most economical to produce, with the lowest energy costs. To put it in a nutshell, the production of our BUCO plate ice takes place at half the operating costs compared to all drum systems. In addition, energy can also be saved when storing our ice, as our BUCO plate ice with a temperature of -0.5°C can be stored in silos of -1°C in a more energy-saving way at -1°C to -2°C at far lower costs compared to storing flake ice at -10°C.

Our chip ice is therefore optimal in terms of heat transfer and economy. Due to the temperature close to 0°C, there are further advantages of our ice, such as round and no sharp edges and no hypothermia (-8°C and thus freezer burn damage), as well as less lumping during transport or storage.

Test series evaluation with a Buco ice machine on part of the end customer

In order to maintain freshness and quality and thus generate the highest possible price for freshly caught fish or seafood, controlled cooling is the main task of the fish and seafood industry. The cold chain must remain closed and there must be no uncontrolled rise in temperature, even and especially during longer transport routes. The cold chain begins with the catch and a direct r cooling to approx. 0 °C as quickly as possible. Ice, close to freezing point at -0.5°C - 1°C (not subcooled) and due to this temperature with blunt edges is ideal for cooling and e storing the fish or seafood on ice. BUCO ice maker bring with it all of these properties, in addition to low-cost production with evaporation temperatures of T0= -8°C - -10°C, which is less than half the temperature required for the production of flake ice (evaporation temperature -20°C) and thus has a massive and daily impact on the production costs of ice machines for the end consumer.

What to Look for in an Industrial Ice Maker? Industrial ice in use for cooling fish

The doubled price for the same amount of ice in market flake ice plants was the reason why fish processing companies decided and continue to decide to test our ice for quality in their own processing and application and to compare whether Buco crushed ice is comparable or even better than flake ice, in order to confirm the full advantage of the quality of Buco ice machines in terms of price per kg of ice versus price per kg of fish.

Flake ice and plate ice in comparision to select the best industrial ice machine

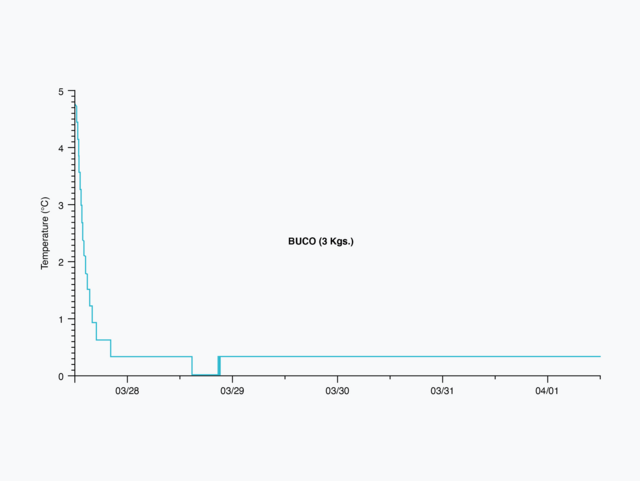

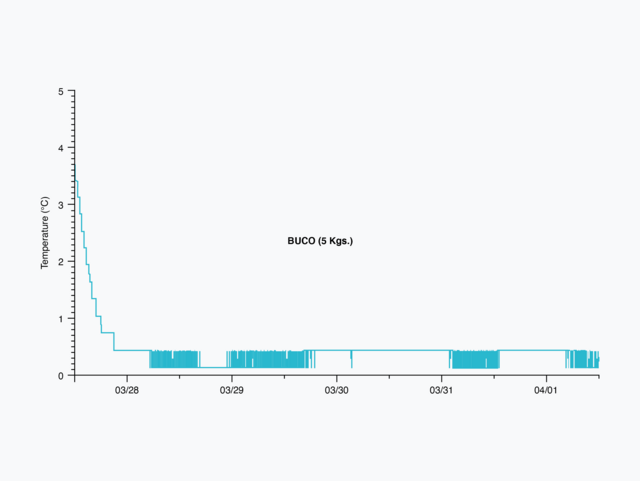

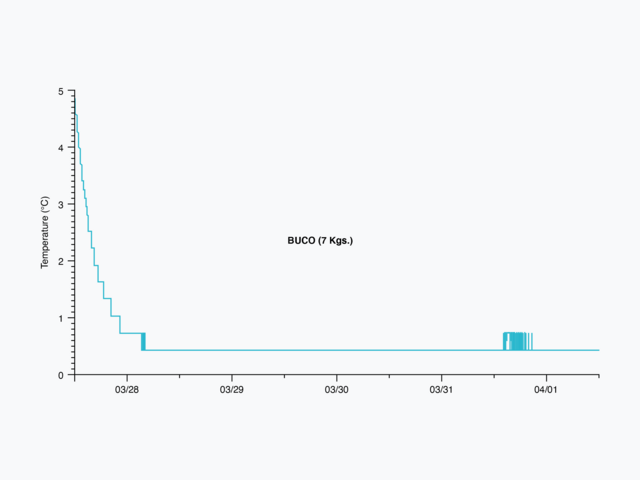

The following series of tests by companies in the salmon processing industry provided information on this. For this purpose, a constant quantity of 20 kg of grade A salmon fillets was tested in different phases of cooling. 10 different test series were carried out with salmon in fish boxes. These fish boxes contained 3 kg Buco ice, 5 kg Buco ice and 7 kg Buco ice.

These fish boxes were stored in a cold room at a constant temperature of 0°C for 120 hours. Thermometers were positioned inside the salmon to continuously measure the internal of the fish continuously over this period. (Some fluctuations in the measured temperatures are due to the highly sensitive measuring device). Finally, it was found that the temperature of the salmon was constant at 0.5°C internal temperature, as shown by the tests on the three series of measurements of 3, 5 and 7 kg Buco ice in the fish boxes. The temperature diagrams showed that the internal temperature of the salmon was reduced from an initial temperature of 3.5°C to 5°C to a final temperature of 0.3°C to 0.5°C over a period of 10 - 12 hours, confirming homogeneous cooling. Effectiveness of the Buco plate ice to cool the salmon has been proven.

Following ice machine advantages have to be noticed:

- Industrial ice machine for fish cooling with half the power consumption due to high evaporation temperatures

- Flake Ice Machine for fish cooling has no mechanical scraper as spare part

- Ice machine made entirely of stainless steel, mandatory for fish cooling

- Ice making machine for fish cooling with Ideal ice temperature with -0.5 ° C, hardly undercooled

- Industrial ice machine for fish cooling with no sharp flake ice edges

- Flake ice does not freeze during storage due to the high ice cooling temperature -0.5 ° C

- Ice maker with adjustable Flake Ice thickness and chip piece size

- Ice machine with minimal refrigerant content

Conclusion

Profitability and ice quality out of the Buco ice maker for cooling could be confirmed.

How Much Does It Cost to Own an Industrial Ice Machine?

The energy cost comparison to cool the salmon in this application case between an industrial ice machine and a conventional drum system showed:

Example: 30 to ice / day

Required refrigerating capacity including losses: approx. 150 kWref

Electrical power required to drive the refrigerating machine:

-30 / 35 °C with COP = 1.8 Pel = 84 kWel – drum system flake ice

-10 / 35 °C with COP = 3.6 Pel = 42 kWel – BUCO Ice Machine

Additional drives: 6 kW

Price for electricity: 0.15 € / kWhel

Running costs at -30 °C: 324 € / day or 11 € / ice – drum system

Running costs at -10 °C: 173 € / day or 6 € / ice – BUCO Ice Machine

Ice machine savings in comparison to flake ice production costs:

Savings: 151 € / day using the Buco Ice Maker

for 300 days of production: 45,300 € / year savings in electricity costs using the Buco Ice Machine

Furthermore in industrial refrigeration, our manufactured Buco Plate Ice can be stored at a temperature of -0.5°C in silos of -1°C in a more energy-efficient way and at a much lower cost than compared to Flake Ice (-10°C).

What to look for in an Industrial Ice Maker to produce industrial ice so-called flake ice?

From a qualitative point of view, it was concluded that BUCO crushed ice gives slightly better cooling results compared to the results of cooling with flake ice, as it is not supercooled (-8°C). It was also confirmed that the BUCO plate ice out of their ice machines has no sharp edges and during transport or storage the BUCO crushed ice clumps very little. So in all aspects that are important to the customer, our Buco crushed ice scored over Flake Ice.