Heat Transfer Technology

Industrial solutions

Our company specialises in the planning, development and optimisation of industrial processes in the fields of process engineering, energy plant construction and food technology. We combine decades of engineering excellence with modern methods of digital process analysis and optimisation.

Stability through experience

The foundation of our success is a team of highly qualified process engineers with many years of practical experience in the design and integration of complex plants. The above-average length of service of our employees ensures continuity in projects, a deep understanding of processes and strong customer relationships.

This in-depth expertise covers:

- Thermal and mechanical process engineering

- Energy efficiency and heat integration in production plants

- Hygienic design and process safety in the food industry

- Plant optimisation taking regulatory requirements into account

Innovation through new skills

Alongside the stability of our core team, we invest specifically in recruiting young engineering talent. These individuals bring expertise in modern tools, including AI-supported simulation software, machine learning methods for process optimisation, and digital twins for predictive plant analysis.

The integration of these new skills into our existing team creates a two-way transfer of knowledge: experience meets algorithmic methodology, and proven engineering principles are expanded with data-driven approaches.

Our way of working

As a stable, high-performance unit, we work in an interdisciplinary and project-based manner. The combination of many years of plant experience and digital engineering tools enables us to design processes more precisely, simulate them more quickly and operate them more economically.

We see ourselves as a reliable partner for:

- Conceptual design and basic engineering of new production plants

- Process optimisation and revamping of existing systems

- Energy and resource efficiency studies

- Technical due diligence and plant consulting

Excellence as standard

For us, technical excellence is not just a marketing term, but something we put into practice every day. It is reflected in the quality of our calculations, the reliability of our designs and the long-term performance of the plants we support.

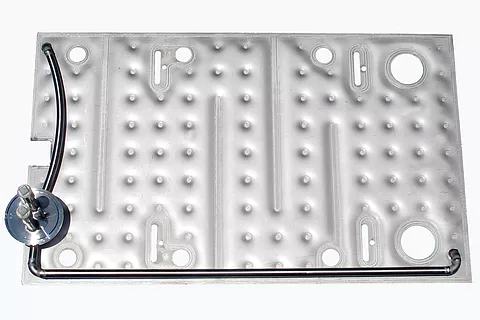

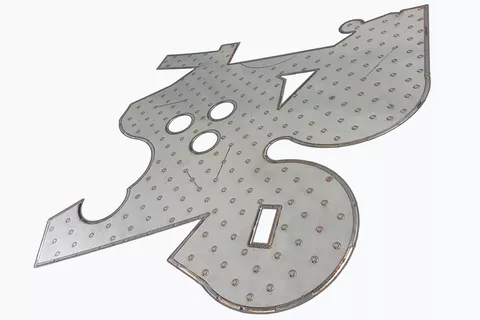

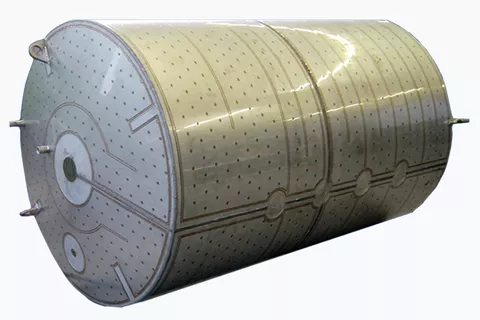

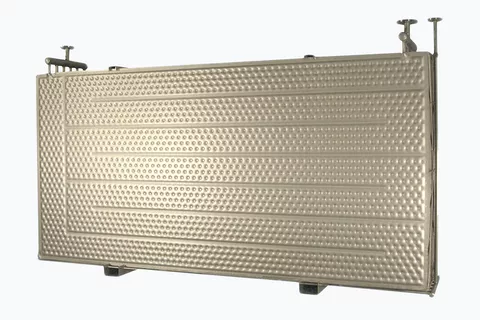

Our Products

We primarily focus on thermo process technology and the calculation of heat exchangers as heat transfer plates. This is achieved through optimized calculations for heat transfer and pressure drop. Subsequently, this is implemented in terms of construction and manufacturing by using stainless steel or mild steel heat transfer plates, depending on the application and heat transfer requirements. To compare various heat exchangers and make informed decisions, it is important to consider the advantages and disadvantages of each product and perform a cost-benefit analysis. An essential factor in this regard is operational safety and stability, allowing the company to save energy and use heat exchanger products more economically.

Solutions

The main focus is on integrating the heat exchange plate or heat exchange system made of stainless steel or mild steel into complex process plants of various applications. Our products and services meet the highest quality standards. Additionally, they are individually tailored to meet the spatial, hygienic, and process requirements of our customers.

Examples Of Our Daily Heat Transfer Tasks

- Do you have notable load peaks to cool at changing flows and temperatures?

- Do you want to minimize the refrigerant volume of your unit in operation?

- Do you want to exploit your polluted exhaust gases or steam for heat recovery?

- Do you want to cool fluids with corrosive or bioactive components? ( e. g. seawater)

- Do you want to move a liquid in an agitator vessel and temper it at the same time?

- Do you have high standards for hygiene and need access at any time without long disassembly, without gaskets to replace?

- Do you want to cool food or beverages down to near the freezing point?

- Do you have to guarantee safety of operation of your cooling device, even during maintenance?

- Do you want to increase your cooling capacity by using your old, existing refrigeration plant?

- Do you want to release your electricity grid from electricity peaks produced by a refrigeration unit?

- Do you know drum ice makers, but want to cut ice production costs to half the amount?

- Do you want to cool fish or meat down to near the freezing point?

- Do you need a huge cooling capacity, but have limited floor space available?

Any questions?

Robert

General Manager department application consultancy

Telephone: +41 (0)31 310 2411

Telefax: +41 (0)31 310 2415

E-mail: sales@htt-ag.com