Pillow Plate Heat Exchangers

High-Efficiency Thermal Solutions for Industrial Applications

Do you want to know more about Pillow Plates?

Product Leaflet BUCO Dimple PlateWhat Are Pillow Plate Heat Exchangers?

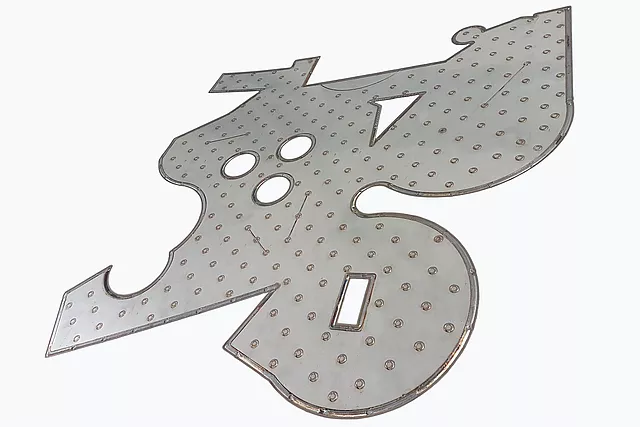

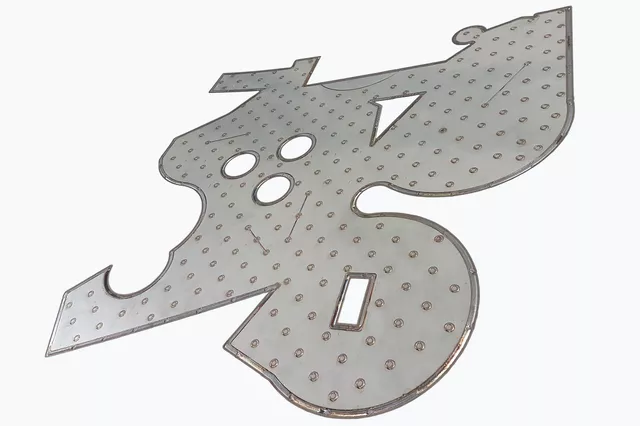

Pillow plate heat exchangers represent a sophisticated thermal management technology that has revolutionized industrial heat transfer applications across multiple sectors. Pillow plates are high-performance heat transfer panels formed by welding two metal sheets – typically stainless steel or carbon steel – followed by inflation to create a three-dimensional, dimpled structure. This geometry increases the surface area and promotes turbulent flow, even at low Reynolds numbers, resulting in significantly improved heat transfer efficiency.

Pillow Plates are available in two main configurations:

- Single Embossed Pillow Plates feature one flat sheet and one inflated sheet, making them ideal for tank jacket applications and vessel wall integration. This configuration provides moderate heat exchange performance with economical design characteristics, commonly selected for dimple jacket installations and tank shell cooling applications.

- Double Embossed Pillow Plates incorporate symmetrical inflation of both sheets, creating standalone heat exchanger modules with enhanced thermal performance. This design enables high turbulence generation, increased heat transfer coefficients, and compact thermal solutions with superior heat transfer rates.

Pillow plates are high-performance heat transfer panels formed by welding two metal sheets.

What are the advantages of Pillow Plate Heat Exchangers?

Single embossed Pillow Plate Heat Exchangers

- Individual designs of a single and double side pillow panel exchangers in size, shape and material enable flexible use due to a freely programmable CNC laser welding system.

- Low pressure loss in the shell space due to flat parallel ducts of a panel due to thin-walled plates and an automated welding process.

Double embossed Pillow Plate Heat Exchangers

- Individual designs of a double embosed pillow panel exchangers in size, shape and material enable flexible use due to a freely programmable CNC laser welding system.

- Lots of exchange surface in little space due to small thermoshelf spacing of up to 2mm clear width.

- High efficiency due to favourable flow routing (counterflow and crossflow).

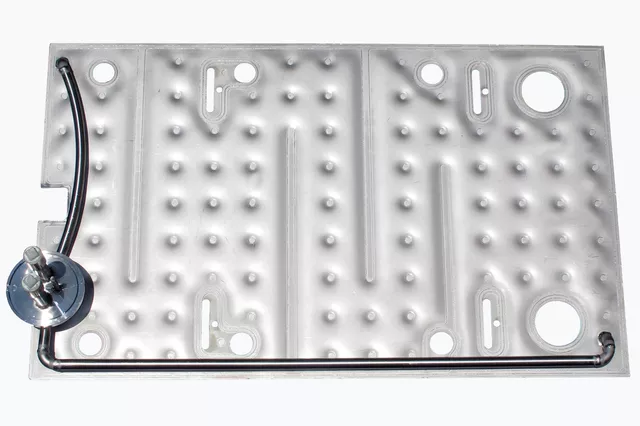

Single Embossed Pillow Plate Manufacturing Possibilities

Manufacturing options for single embossed pillow plates, such as minimum and maximum lengths and widths, connections and variable channel guides. Demonstrations of use cases.

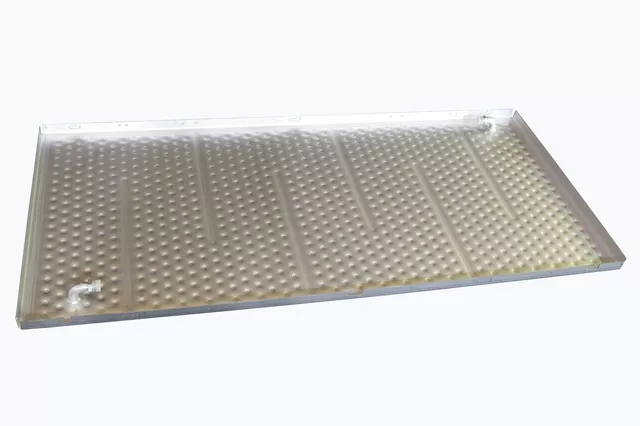

Double Embossed Pillow Plate Manufacturing Possibilities

Manufacturing options for double embossed pillow plates, such as minimum and maximum lengths and widths, connections and variable channel guides. Demonstrations of use cases.

How Do Pillow Plate Heat Exchangers Work?

Pillow plates are integrated into thermal systems where fluids flow through the internally welded channels. The flow path can be precisely designed using CNC-controlled laser welding to optimize thermal efficiency and minimize dead zones. Turbulence within the plates enhances heat transfer, allowing for reduced panel volume and smaller system footprints.

In jacketed tanks, double-embossed plates also act as flow guides, ensuring homogenous temperature distribution and optimal mixing. Withstanding pressures over 100 MPa and temperatures up to 800 °C, pillow plates are a robust solution across many sectors.

Pillow plates are a robust solution across many sectors.

Key Advantages of Pillow Plate Technology: All the key benefits of Pillow Plates at a glance

Thermal Performance and Efficiency

Pillow plates offer significant advantages over traditional heat exchanger technologies through several key engineering principle.

- High heat transfer coefficients even under low flow conditions

- Homogeneous temperature distribution

- Compact design with high surface-to-volume ratio

Resource and Cost Efficiency

Reduced steel consumption compared to tube bundle heat exchangers while maintaining equivalent or superior thermal performance.

- Less material usage compared to tube-bundle systems

- Reduced volume of heating or cooling media required

- Lower production and maintenance costs

Durability and Reliability

Smooth surface finishes and optimized flow patterns minimize particle deposition and fouling, reducing maintenance requirements.

- Pressure-resistant construction

- Long operational lifetime

- Smooth surfaces reduce fouling and enable easy cleaning (CIP-ready)

Design Flexibility

Customizable geometries allow adaptation to specific installation requirements and process conditions. High surface area-to-volume ratios enable substantial heat transfer capacity within minimal spatial requirements, crucial for space-constrained applications.

- Freely programmable welding contours and geometries

- Customizable in size, shape, and surface finishes (pickled, polished, ground)

- Integration into existing or new systems (vessels, tanks, fryers, battery cooling units, etc.)

Pillow plates offer significant advantages over traditional heat exchanger technologies.

Industry-Specific Applications

Food and Beverage

Pillow plates excel in food and beverage applications where precise temperature control and hygienic design are paramount. Applications include fermentation tank temperature control for wine and beer production, dairy processing equipment thermal management, and gentle cooling systems for temperature-sensitive products such as fish, meat, and seafood.

- Fermentation tanks for beer and wine

- Temperature control in dairy and seafood processing

- Frying plates, drying systems, and agitator vessels

Pharmaceutical Manufacturing

In pharmaceutical applications, pillow plates provide precise thermal management in sterile environments, ensuring product consistency and meeting stringent cleanroom requirements. Their smooth surfaces facilitate effective cleaning-in-place (CIP) procedures essential for pharmaceutical manufacturing.

Chemical and Pharmaceutical

The chemical sector utilizes pillow plates in reactor temperature control systems, pipeline cooling applications, and process heat recovery systems. Their corrosion-resistant construction makes them suitable for harsh chemical environments, while their design flexibility allows integration into both batch and continuous processing systems.

- Corrosion-resistant reactor jackets

- Evaporators and condensers in process systems

- Cleanroom-compliant installations with CIP

Energy and Environmental Technology

Pillow plates serve critical roles in renewable energy systems, including biogas plant digesters, waste heat recovery systems, and solar thermal applications. Their efficiency in heat recovery processes contributes to overall system energy optimization.

- Heat recovery from biomass or waste streams

- Solar and geothermal exchanger units

- Biogas digesters and condensers

Automotive and Electronics Cooling

The growing electric vehicle market has created new applications for pillow plates in battery thermal management systems and electronic component cooling. Their compact design and efficient heat transfer characteristics make them ideal for space-constrained automotive applications.

- EV battery cooling systems

- Electronic component thermal management

- Integration into compact control unit housings

Pillow plates provide precise thermal management in sterile environments.

Technical Specifications Overview

| Feature | Specification |

| Dimensions | From DIN A5 (148 × 210 mm) up to 14,000 mm length × 2,000 mm width |

| Plate Thickness | 0.8 – 3.0 mm (double embossed); up to 12 mm (single embossed) |

| Operating Pressure | Up to 50 bar for standard applications, with capability for pressures exceeding 100 MPa in specialized designs |

| Temperature Range | Up to 800°C operational capability |

| Materials | Stainless steel (AISI 304/316), titanium, carbon steel, nickel alloys |

| Surface Finishes | Pickled, polished, brushed |

| Welding Methods | CNC-controlled laser welding, resistance welding |

| Certifications | TÜV, PED (Pressure Equipment Directive 2014/68/EU), ASME, TR CU (GOST) |

Pillow plate heat exchangers represent a sophisticated thermal management technology.

Customization Options of Pillow Plates

Modern pillow plate manufacturing enables extensive customization to meet specific engineering requirements. Customization options include specialized welding patterns for optimized fluid flow, integration with tanks and structural components, varied connection types including flanges and threaded ports, and custom cut-outs for instrumentation and piping.

This flexibility allows pillow plates to serve multifunctional roles, combining heat exchange with mechanical support and even radiation shielding in specialized applications.

- Spot and seam weld patterns for tailored flow control

- Cut-outs for cables, pipes, or instrumentation

- Thermoplate integration for radiation shielding

- Connections: flanges, threaded sockets, welded nozzles

Pillow plates combine heat exchange with mechanical support and even radiation shielding in specialized applications.

Maintenance and Hygiene

Pillow plates are engineered for minimal maintenance requirements and easy cleaning procedures. The smooth stainless steel construction resists corrosion while the simplified geometry reduces areas where debris accumulation can occur. Cleaning methods include automated CIP systems for food and pharmaceutical applications, steam cleaning for routine sanitization, and mechanical cleaning through brushing or spray-wash systems.

- Ideal for hygienic environments thanks to flat, cleanable surfaces

- Compatible with steam cleaning and automated CIP systems

- Resistant to corrosion and scaling

Flat surface pillow plates ensure minimal maintenance requirements and easy cleaning.

Quality Assurance and Compliance

Manufacturing compliance with international standards ensures safe and reliable operation across global markets. Key certifications include TÜV certification for pressure vessels and safety systems, PED compliance for European pressure equipment regulations, ASME certification for US market applications, and TR CU (GOST) certification for Eurasian Economic Union markets.

Manufacturing compliance with international standards ensures safe and reliable operation.

Why Choose Pillow Plate Heat Exchangers?

Pillow plates offer a distinct advantage over traditional tube or shell heat exchangers in performance, durability, and flexibility. With over 50 years of engineering evolution, they are now a leading solution for modern thermal applications demanding energy efficiency and compact design.

Ready to Design Your Next Heat Exchange System?

Let’s find the right pillow plate solution for your process.

Contact our engineering team today for a free consultation.

We support you in developing customized thermal equipment that ensures performance, hygiene, and cost efficiency.

Let’s find the right pillow plate solution for your process.

Technical Summary

- Construction Types: Single embossed (tank walls), double embossed (exchangers)

- Materials: Stainless steel, carbon steel, nickel alloys, titanium

- Performance: Up to 800°C and >100 MPa

- Cleaning: Easy-to-clean, CIP and steam compatible

- Design: CNC laser welded, custom contours and flow guidance

- Certifications: CE (PED 97/23/EC), ASME, TÜV, TR CU

Outlook: Future Developments and Engineering Innovations

Ongoing research and development efforts focus on optimization through finite element analysis for precise design calculations and advanced software tools for performance prediction. These developments continue to enhance the efficiency and applicability of pillow plate technology in emerging industrial applications.

The combination of proven thermal performance, design flexibility, and manufacturing reliability positions pillow plate heat exchangers as a key technology for energy-efficient industrial processes and sustainable thermal management solutions across diverse engineering applications.

Pillow plate heat exchangers are a key technology for energy-efficient industrial processes.

Frequently asked questions

A pillow plate is a technical development in which two sheets of stainless steel or structural steel are welded together over their entire surface. The characteristic corrugated surface with a circular welding pattern is created by an inflation process using nitrogen under pressure.

Pillow Plate heat exchangers can be installed directly in tanks to transfer large amounts of heat or to achieve an even temperature distribution. In tanks with agitators, they also serve as a guide surface for the flow, which contributes to optimum mixing and homogeneous heating or cooling.

The main advantages include:

- Individual designs in terms of dimensions, shape and material for flexible use

- Easy cleaning thanks to easily accessible surface

- Homogeneous, product-friendly temperature control

- Adaptability to various application criteria

Pillow plates are used in various industries, in particular

- Food and beverage industry

- Chemical industry

- Energy industry

Some important technical specifications are

- Dimensions from DIN A5 up to 14000 x 2000 mm

- Operating pressures up to 70 bar

- Wall thicknesses from 0.8 - 3 mm with double-sided profile

- Can be used for various media such as water, glycol, thermal oil or steam

Pillow Plates are manufactured using a special inflation process. Two sheets are first welded together using laser or resistance welding techniques. The gap between the sheets is then put under pressure, creating the characteristic deformation.

With single-sided embossed pillow plates, only one of the two plates deforms, namely the upper, thinner welded-on plate, while the other, the lower, thicker plate, remains flat. These are often used as double shells for containers. Pillow Plates embossed on both sides are created when both plates take on a pillow-like shape and are often combined to form heat exchanger stacks.

Thanks to their undulating surface, they promote the mixing of liquids, which leads to high heat transfer rates. However, the level of efficiency depends on the specific application and operating conditions.

The flat outer surface is easy to clean and is suitable for applications with high hygiene requirements. However, the inside can be more difficult to clean due to the weld seams and is therefore more suitable for non-fouling media.

The cost varies depending on the design, material and application. However, in many cases they offer good value for money due to their efficiency and longevity.

Single embossed Pillow Plates

- Construction: Consists of a thicker base plate and a thinner top plate. Only the top plate is deformed by the inflation process, while the base plate remains unaffected.

- Use: Often used as so-called dimple jackets, which are applied to vessel or tank walls or are the vessel wall itself to enable heat transfer.

- Applications: Ideal for applications where one-sided heat transfer is required, e.g. temperature control of tanks or vessels.

Double embossed pillow plates

- Construction: Both plates (top and bottom plate) are deformed in the same way on both sides by the inflation process, creating a double-sided profile.

- Application: Mostly used in heat exchanger units where heat transfer is required on both sides.

- Areas of application: Suitable for compact heat exchanger solutions with high efficiency, e.g. in the food, chemical or pharmaceutical industries.

In summary, the two types differ primarily in the type of deformation (one-sided vs. two-sided) and the resulting application possibilities.