Dimple Jacket Engineering Services

Efficient Solutions for Temperature Control

Do you want to know more about Dimple Jackets?

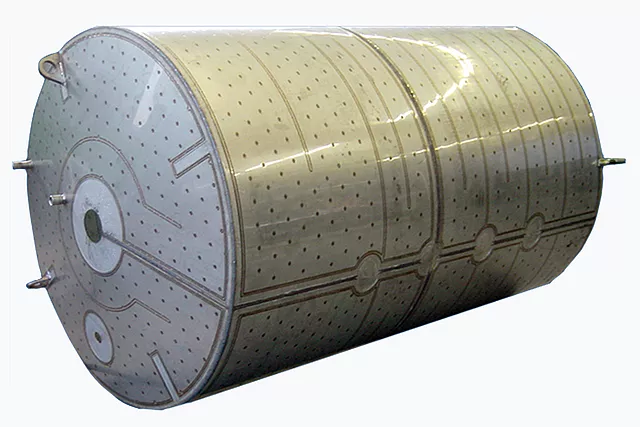

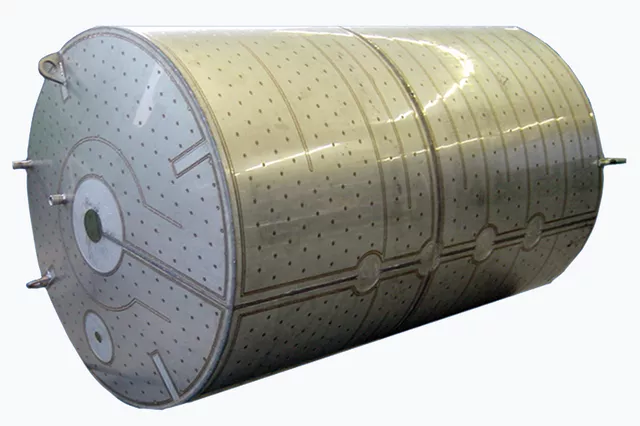

Product Leaflet BUCO TankwallsWhat Are Dimple Jackets?

Precise temperature control is indispensable in industrial processes to ensure product quality, energy efficiency in terms of maximum savings, and operational safety. Dimple jackets, also known as pillow plate jackets, are state-of-the-art solutions for thermal management and are widely used in sectors such as food processing, pharmaceutical, chemical plant engineering, and energy technology. These plate jackets guarantee uniform heat transfer, robust performance, and cost-efficient operation.

What Is a Dimple Jacket?

Definition and Operating Principle

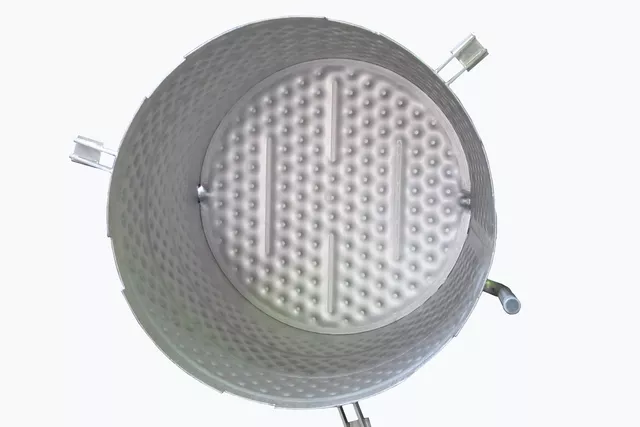

A dimple jacket is made of two stainless steel sheets that are welded together at defined points or lines. The sheets are then hydraulically or pneumatically inflated, creating flow channels for heating or cooling media, such as water, glycol, steam, thermal oil, or refrigerants. This design ensures efficient and uniform heat transfer across the entire vessel surface.

Dimple jackets, also known as pillow plate jackets, are state-of-the-art solutions for thermal management.

What are the advantages of dimple plates?

Single embossed dimple plates

- Any design possible according to application criteria or demand.

- Any welding contour of the pillow plate is freely programmable

- High heat transfer coefficient with low pressure drop

- No surface damage on the inside of the tank due to the laser-welding process.

Double embossed dimple plates

Possibilities of using an external clamp-on plate on an existing tank, which is not welded in. The mounting on the existing tank is done by means of screw connections or tension straps, as well as

- Any kind of welding free programmable. Cut-outs for pipes, legs. etc.

- Attractive investment costs of a pillow plate due to thin-walled plates and an automated laser welding process

Single Embossed Dimple Plates for Process tank cooling

Any design possible according to application criteria or demand. Any welding contour of the pillow plate is freely programmable.

Double Embossed Clamp on Pillow Plates for Process tank cooling

Possibilities of using an external clamp-on plate on an existing tank, which is not welded in. The mounting on the existing tank is done by means of screw connections or tension straps.

Materials and Surface Treatments

Before deployment in demanding industrial environments, dimple jackets are manufactured from carefully selected materials and further refined to meet specific hygiene and process requirements. Various materials and surface finishes are used to achieve optimal results with respect to durability, stability, and cleanability:

- Materials: Commonly used grades are AISI 304 and AISI 316L stainless steels; titanium is available for special applications.

- Surface Treatments: Options include pickling, polishing, or grinding – selected based on stringent hygiene requirements, particularly in the food and pharmaceutical industries.

- Media Compatibility: Suitable for water, glycol, steam, thermal oil, and various refrigerants, supporting a wide range of process requirements.

Dimple jackets are manufactured from carefully selected materials.

Key Advantages and Benefits of Dimple Jacket Technology

Dimple jacket technology offers a variety of advantages that directly impact efficiency, safety, and economic viability in industrial processes. The most important benefits include:

- Uniform temperature distribution across the full surface of tanks or vessels – for optimal product quality and process safety.

- High heat transfer coefficients with minimal pressure drop – for faster heating/cooling cycles and reduced energy consumption.

- Reduced material and media usage.

- High pressure resistance (tested up to 100 bar).

- Easy cleaning and maintenance; compatible with CIP (Clean-In-Place) systems.

- Long service life and low overall lifecycle cost.

- Energy-saving through efficient use of heating/cooling media and minimized thermal losses.

Dimple Jacket Technology stands for high heat transfer coefficients with minimal pressure drop.

Types of Dimple Jackets

To cater to various industrial requirements, dimple jackets have been developed in several configurations that can be custom-tailored in design, shape, and mounting method depending on application needs. The available versions offer unique benefits for a range of uses.

Weld-In Jackets

- Integrated during tank manufacturing.

- The base sheet provides structural support, while the embossed upper sheet delivers optimal heat transfer.

- Suitable for cylindrical, conical, and curved tank sections.

Clamp-On Jackets

- Retrofitting by means of clamps, bolts, or tension straps.

- Use of thermal paste (e.g., BUCOmastic) is possible to boost performance.

- Ideal for upgrading existing tanks and vessels.

Manufacturing and Quality Assurance

- CNC-controlled laser welding guarantees precise and individually adjustable weld patterns for optimal flow and heat transfer.

- After inflation, plates are inspected and processed to ensure quality and performance.

- Rigorous testing and certification according to international standards (PED, ASME, TR CU, TÜV) ensure reliability and global applicability.

Flexible Applications

- Adaptable shapes: rectangular, round, conical, or segmented – to fit various industrial containers and processes.

- Broad application spectrum: tank heating, ice storage, reactor cooling, battery management, and much more.

- Industries served: food, pharmaceutical, chemical, energy, e-mobility, and environmental technology.

The available versions offer unique benefits for a range of uses.

Technical Consulting and Project Support

- Professional review of construction drawings and process data to guarantee optimal system design.

- Tailor-made solutions: channel routing, flow optimization, and media selection for maximum efficiency.

- Long-term support: continuous performance optimization and system updates.

We provide tailor-made solutions and long-term support.

Dimple Jackets – Technical Overview

To provide a rapid overview of the key technical features, the following specifications are particularly relevant for planning, design, and operation of a dimple jacket:

| Feature | Specification / Details |

| Maximum dimensions | Up to 14,000 × 2,000 mm |

| Wall thickness | 0.8 – 3 mm (double layer); up to 12 mm (single layer) |

| Operating pressure | Up to 50 bar (single-sided plates tested up to 100 bar) |

| Integration options | Welded or clamped (Clamp-On) |

| Certifications | PED, ASME, TR CU, TÜV |

| Surface treatments | Pickled, polished, ground; CIP-compatible, accessible, polishable |

| Media compatibility | Water, glycol, steam, thermal oil, refrigerants |

| Industries | Food, pharmacy, chemical, energy, e-mobility, environmental technology |

Various materials and surface finishes are used to achieve optimal results.