Heavily fluctuating volume flows or inlet temperatures?

Fluctuating amounts of water or water inlet temperatures cause this to affect the performance. This can have a variety of reasons. It is important to the customer that his product can retrieve the required performance specified in the technical data sheet, so that its cooling process remains stable. We recommend a dimple plate and or dimple plate heat exchanger system in the tank, which compensates peaks loads in a simple way, without control systems.

However, the respective conditions of use must be clarified. There are a variety of possible solutions. This does not always have to be a heat exchange plate system in the tank. A falling film chiller with a larger storage tank can also be considered, as well as a storage tank with a hot and cold section in which different water quantities as well as water inlet temperatures are mixed in order to feed a constant water return quantity from the process back to the falling film chiller. Depending on the load profile kWh over 24 hours of the day, a Buco ice silo can also be considered. This means that a fluctuating amount of water in the inlet is controlled by ice melting to control the water return temperature to the process. The more we understand your process, the better we can offer alternatives for you to evaluate according to investment and operating costs.

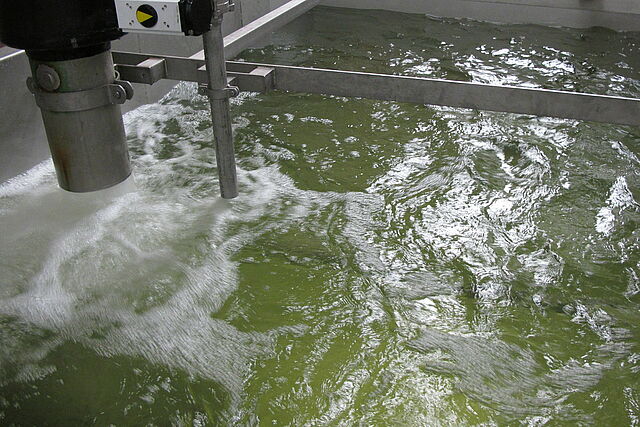

The optimal solution is important to us, using an optimised engineering solution. It does not necessarily have to be a new investment with a new installation, but it is important to recognise the possibilities that are available. It has to be checked whether existing storage tanks are available or existing coil-in-tanks with existing agitators. We have this experience to make these suggestions to you and to discuss possible solutions with you.

Far too often, day-to-day business is subject to the individual problems of the manufacturing process.

In some cases, a strategic alignment of the company does not seem necessary because sufficient profits are still being made or profits have just been increased. In other cases, the situation is unexpectedly exacerbated in the short term by the current price pressure in the industry.

While the meetings in the companies with sufficient or increasing profits are still relaxed, the meetings of the companies under pressure are harsher, technology as well as the finance department agree that savings have to be made. The red pencil is applied, whereby it remains questionable whether the decided savings do not also result in qualitative disadvantages of the product.

But for all the companies described, in the world of globalisation, it is true that local and international competition increases prices and the pressure in day-to-day business rises steadily.

A primary aspect, which is all too often ignored, is the constant optimisation of processes in all companies, irrespective of rising, stagnating or falling profits or momentary losses.