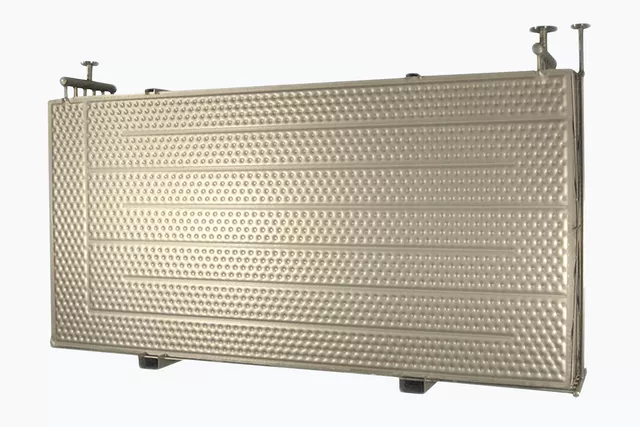

Pillow Plate Heat Exchange Systems

Industrial heat exchange systems based on pillow plates provide an efficient solution for cooling, heating, and heat recovery in process technology plants. Thanks to their flexible design, they are suitable for both liquids and gases, even at high pressures or when dealing with contaminated media.

How a Pillow Plate Heat Exchange System Works

Pillow plate heat exchangers consist of double-profiled thermal sheets whose corrugated surface creates large heat transfer areas. This design allows for effective handling of challenging media such as vapors, highly viscous liquids, or particle-laden streams. The systems can be designed to automatically compensate for temperature peaks and load fluctuations – either via control technology or through a buffer volume in the tank.

Advantages of Pillow Plate Heat Exchangers

- High Heat Transfer Coefficient (k-values): Corrugated thermal sheet surfaces enlarge the effective transfer area.

- Efficient Flow Guidance: Optimally sized cross-sections reduce pressure losses.

- Reliability with Contaminated Media: Even exhaust air, waste water, or liquids containing solids can be reliably cooled or heated.

- Robust Stainless Steel Construction: Durable and resistant to corrosion.

- Easy Maintenance: Open construction allows for fast inspection and cleaning.

- Flexible Design: Pillow plates can be customized in geometry, material, and format to suit the customer’s application.

Typical Industrial Applications

Pillow plate heat exchangers are established in many industries:

- Process Cooling and Heating: Liquid-liquid and gas-liquid processes, even with fluctuating flow rates; used in chemical, food, and pharmaceutical industry circulation systems.

- Heat Recovery: Utilization of contaminated exhaust and air streams; recovery from condensate and solvent vapors; energy savings in paper, pulp, and biomass processing.

- Refrigeration and Ice Water Plants: Production of ice water at +0.5°C for dairies and food operations; use of ammonia (NH₃) as an efficient, eco-friendly refrigerant; high operational safety via precise process control.

Comparison to Traditional Heat Exchangers

Compared to shell-and-tube heat exchangers and coil systems, pillow plate exchangers provide decisive benefits:

- No clogging with contaminated media

- Significantly reduced maintenance and cleaning efforts

- Long service life due to fully welded stainless plates

- Operable at pressures up to 50 bar

- Flexible formats, including insertion exchangers or jacket coolers

Technical Overview

Key technical data at a glance:

- Power range: 10 kW to 1,000 kW (single systems up to >2.4 MW for ice water plants)

- Plate sizes: up to 4,000 × 2,000 mm

- Wall thickness: 0.8 / 0.8 mm to 3 / 3 mm

- Operating pressures: up to 20 bar (special versions up to 50 bar)

- Configurations: with and without tank, compact units up to 100 kW, or integrable into large systems

- Media: liquid-liquid, gas-liquid, brine, water, steam, thermal oil

- Special features: very low pressure losses, easy cleaning, customizable to tank and plant geometry

Conclusion

Pillow plate heat exchangers offer an efficient, robust, and versatile solution for industrial heat transfer applications. Especially when dealing with fluctuating media flows or contaminated process streams, they have substantial advantages over traditional heat exchangers regarding maintenance, energy efficiency, and process reliability.

FAQ: Heat Exchange Systems – Technical Questions in Detail

Pillow plate heat exchange systems are based on double-profiled thermal sheets (called pillow plates), which, through variably welded constructions, provide a large, structured surface for heat transfer. Unlike conventional shell-and-tube or plate heat exchangers, pillow plate systems offer maximum flexibility in terms of form, size, and material and can be tailored to each process’s requirements. They are especially efficient with problematic media and provide minimal clogging tendency and easy cleaning, as the media flows over the large, low-resistance corrugated surfaces. These systems also feature high resistance to pressure and temperature fluctuations without sacrificing stability, combined with very high k-values due to the minimal pressure drop and enlarged surface area.

The principle is based on two separate flow paths for different media within cavities between the corrugated pillow plates. The large profiled surface enables a high heat flux (liquid/liquid or gas/liquid). The plate contouring ensures strong turbulence, enhancing heat transfer and reducing deposits. The system can be designed with a buffer volume or automated control to offset temperature peaks and load variations, ensuring stable and safe process management even with dynamic operating conditions.

Pillow plate systems are extremely flexible and can handle essentially all conventional industrial media, such as water, steam, thermal oils (for heating/cooling), brines, refrigerants (e.g., ammonia), process gases, as well as sludge-laden, viscous, or heavily soiled liquids from wastewater, biomass, or paper processing. Even aggressive, adhesive, or abrasive media are manageable due to robust construction and specialized corrugation, with extended cleaning intervals and simplified maintenance.

Industries include:

- Paper and pulp: energy recovery from condensate and process steam, condensation and energy savings with high-volume flows

- Food industries: pasteurization and cooling of liquids, ice water production (e.g., dairies), flake ice for food processing

- Chemical, pharmaceutical industries: process cooling, solvent condensation, handling of particle-laden process flows

- Wastewater/environmental: heat recovery from exhaust air, industrial effluent, biomass processes

Advantages are always high energy efficiency, low operating costs, flexible design options, and safe handling of even very contaminated or difficult media.

Pillow plate systems are usually designed as open types, so plates can be individually inspected, cleaned, or replaced as needed. Open construction ensures optimal maintenance access, and stubborn deposits or fouling can be cleaned quickly and effectively. The smooth, corrugated surfaces foster self-cleaning by flow effects, which extends intervals and reduces labor and downtime.

Full-welded stainless steel construction and customized channels and wall thicknesses make the systems extremely robust and durable. Operational reliability is achieved through very low pressure drops and the ability to balance temperature/flow fluctuations with buffer tanks or control. The large surface area, targeted flow management, and optimized free channel cross-sections guarantee high energy efficiency.

Pillow plate systems are highly customizable:

- Power range: individual systems from 10 to over 1,000 kW (up to 2.4 MW for large cooling units)

- Plate sizes: up to 4,000 × 2,000 mm

- Wall thickness: 0.8/0.8 mm to 3/3 mm

- Operating pressures: standard up to 20 bar, special construction up to 50 bar

- Media: compatible with all common heat carriers (water, brine, gases, ammonia, thermal oil)

- Design: as rolled cylinders, plates attached to round vessels, compact plug-and-play units, or system integration into existing tanks

- Channel layout and system configuration are individually engineered by experienced engineers.

They enable almost loss-free recovery of process heat from exhaust gases, vapors, and liquids, even when heavily contaminated. The recovered energy can support other process steps or building heating, reducing the need for external energy. This leads to substantial cost savings, improved CO₂ balance, and helps meet sustainability targets, especially in sectors like paper, biomass, and food processing.

For processes with fluctuating volumes and temperatures (e.g., food industry, tank farms), pillow plate systems act as a buffer by employing part of the heat/cooling medium volume, thereby mitigating sudden temperature changes and load spikes to maintain stable process conditions. The high specific surface area of the corrugated plates guarantees efficient heat transfer even with variable flows.

For media with high solid content or strong contamination (e.g., wastewater, biotech, or biomass processes), open pillow plate systems feature large, accessible channels, making inspection, cleaning, or even automatic flushing straightforward. Blockages, fouling, or scale formation are rare and can be further minimized by custom channel designs and targeted flow management.

Yes, pillow plate heat exchangers can act as evaporators for all conventional refrigerants, such as ammonia (NH₃), CO₂, R1234yf, and more. Low internal volume and a high surface area ensure rapid evaporation and high energy yield. PLC controls allow for precise temperature stabilization – for instance, producing ice water at +0.5°C for the food or pharmaceutical industries.

These systems excel at condensing process condensate and solvents (e.g., methanol, ethanol). Plate geometry and individualized channel layout enable stable, energy-efficient recovery and condensation, even with high vapor concentrations. The condensed liquid can be reintegrated into the process, supporting circular economy and resource efficiency.

In the pulp, paper, and chemical industries, where aggressive or high-temperature media are common, pillow plate exchangers’ corrosion-resistant stainless steel construction allows them to function as heating or cooling registers directly inside reactors or tanks. High operating pressures (up to 50 bar in special versions) are possible, enhancing process safety.

Yes, for air drying and filtrate recovery, pillow plate systems provide a compact, powerful alternative to traditional devices. Their open design, targeted air flow, and adaptable plate sizes enable energy-optimized drying and heat recovery, even with moist or contaminated gas streams, as in the paper or filtration industries.

Modular, customizable design means pillow plate systems can be integrated into existing tanks, reactors, or industrial facilities with ease – as rolled cylinders, special plates, or insertion registers, they flexibly adapt to on-site conditions. Integration with control and regulation systems (such as PLC) is also straightforward.

For processes needing high temperatures or special chemical properties (e.g., industrial furnaces or food processing), pillow plate exchangers can operate with thermal oils, brines, and specialized liquids, supporting a wide array of thermal applications such as interchangers, storage solutions, or targeted cooling/heating of specialty media.

What are the advantages with heat exchange systems?

- High U-valued due to slightly corrugated double embossed heat exchanger plate surfaces

- Free cross-sections between the dimple plated optimally adapted to the product flow conditions

- Dimple Plate fully welded design with double tight weld

- These pillow plates are power stable when used with contaminated media

- Easy, fast inspection and cleaning in case of pillow plates

- Longevity thanks to complete double embossed plate stainless steel construction

- For fluctuating power requirement: compensation of temperature and flow fluctuations in the tank

- Simple control by buffer effect

- Minimal pressure loss on the outside of pillow plates

- Pillow plate heat transfer systems for any design according to application criteria or specification