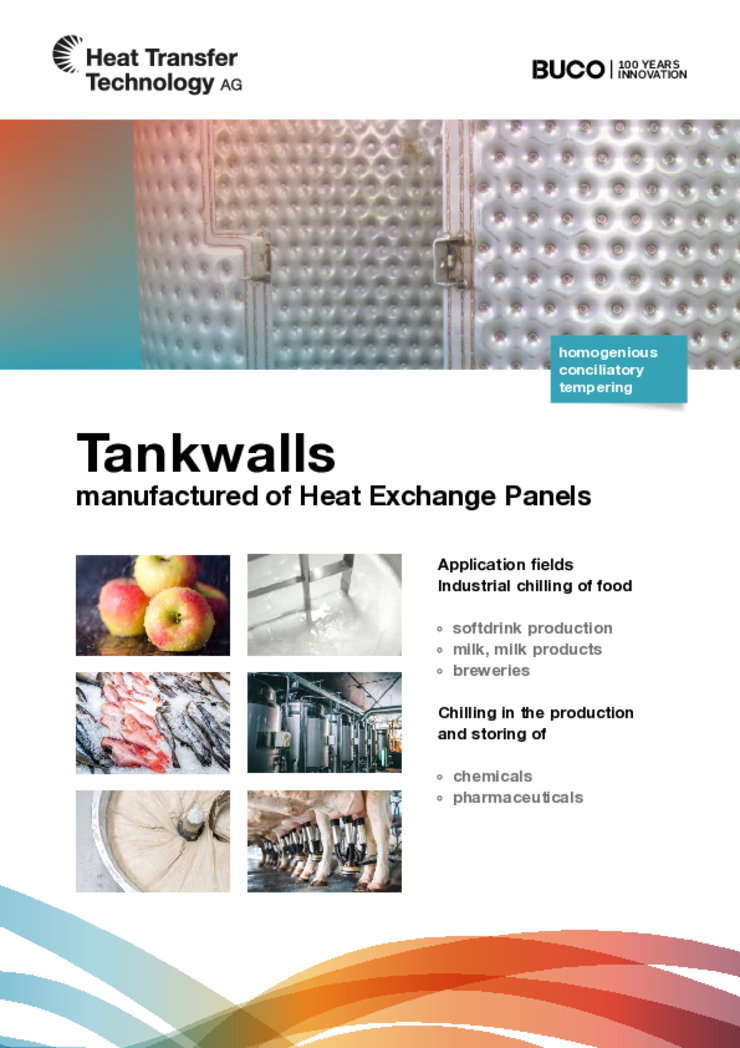

Dimple Jacket

Laser-welded dimple jacket advantages:

- High heat transfer coefficient with low pressure drop.

- No expensive double shell or half pipe construction.

- Less weight than half pipes.

- Low production costs due to automated welding processes.

- Low material costs due to the use of thin metal sheet materials.

- No surface damage on the inside of the tank due to the laser-welding process.

- No cost effective grinding or polishing of the inner surface of the tank inside in case of dimple plates.

- Homogenous and conciliatory tempering of products using dimple plates.

- Long lifetime due to individually choosen materials.

- Welding contours of pillow plates freely programmable.

- Any design possible according to application criteria or demand.

- Kind of weldings for dimple plates free programmable. Cut-outs for pipes, legs. etc.

- Integration into vessels for mechanical and thermal double function.

- Smaller quantities of refrigerant or heating medium due to small plate volumes of dimple plates.

- Clamp-on plates for existing tanks.

- Reliability.