Industrial Ice Machine

Product description and general properties

Industrial ice making machine for industrial flake ice with half the energy costs compared to conventional drum systems

Are you looking for a way to reduce energy costs without sacrificing business operations?

Our BUCO Industrial ice machines are the perfect solution. Not only do they keep your production running smoothly, but also offer power and cost efficiency. By using BUCO Industrial ice machines, companies can significantly reduce their energy consumption, allowing them to cut down their operational expenses while optimizing productivity.

Our industrial ice making machine BUCO, manufactures at half the the energy costs, compared to all drum systems. Our ice is manufactured at a favorable evaporation temperature of Tevap= -8°C to -10°C. Compared to the conventional drum systems, which operate with evaporating temperatures in between Tevap= -20°C to -35°C, our Industrial Ice Maker only consumes half the electric energy for refrigeration and has a COP value twice as favorable as any drum ice system.

Utilisation and added value of the product

What to look for in an Industrial Ice Maker to produce industrial ice so-called flake ice?

Energy consumption advantage of an Industrial Ice making Machine

For the best possible quality of certain foods, you need Industrial Ice cooling through dull ice, without freezer burn on the direct product surface, and with customizable ice thickness. In the first place, with our Industrial Plate Ice or Chip Ice Machine, you do not only get the fastest possible product cooling, but also a continuous cooling. With our flake ice machine an exact ice dosage can be guaranteed, which is necessary for the cooling of high performance cutters in the industrial ice making, f.e. during sausage processing or mixing processes. Our Industrial Ice Making Machine meets high demands on easy cleaning and energy efficiency. Consequently they are also adapted to the respective strict requirements in food processing.

It is possible to use a simple defrosting device which, due to the hot gas supply of large central refrigeration plants, Industrial Ice Machines require fewer refrigerant valves and a simple control system. To produce ice, we do have the efficiency in prior focus.

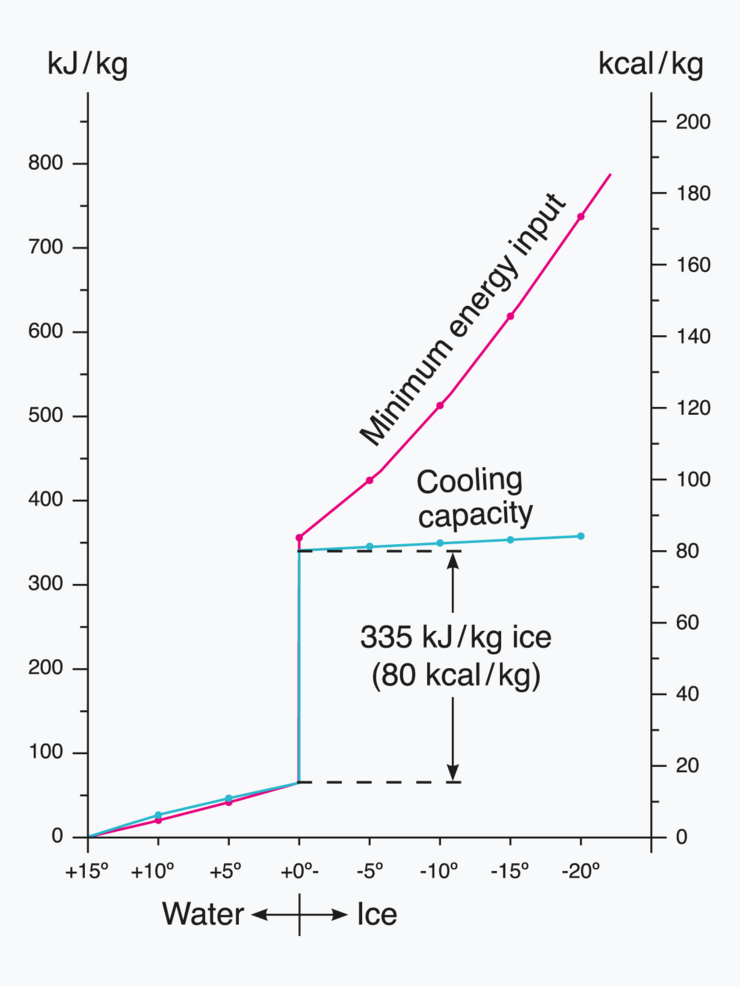

Only by melting of the ice, the heat for cooling of the water is taken from the surrounding. Ice is melting at a temperature of 0°C to water and gives 335 kj per kg ice.

Energy cost comparison of an Industrial Ice Maker Maschine and a conventional drum system for flake ice

Example: 30 to ice / day

Necessary refrigeration power including losses: ca. 150 kWref

Electric power for the drive of the refrigeration machine:

-30 / 35 °C with COP = 1,8 Pel = 84 kWel – Drum system-Flake Ice

-10 / 35 °C with COP = 3,6Pel = 42 kWel – BUCO Ice Pack

Additional drives: 6 kW

Price for electricity: 0,15 € / kWhel

Running costs at -30 °C : 324 € / day or 11 € / to ice – Drum system

Running costs at -10 °C : 173 € / day or 6 € / to ice – BUCO Ice Pack

Savings: 151 € / day

for 300 days production: 45.300,- € / year savings of electricity costs

Therefor we do produce Industrial Plate ice with an evaporation temperature T0= -10°C, which generates ice at a temperatures of T= -0.5°C to -1.0°C. The idea is simple, as the cooling gain for subcooling of the Flake Ice in conventional drum systems is down to T= –8°C, which is only approx. 8% of a higher melting capacity.

Unfortunately this has a high energy consumption impact for the drum ice machines as such: Highest cooling capacity with minimum energy input 335 kj/kg ice at 0°C !

Function of Industrial Ice Makers for industrial flake ice

The industrial ice maker machine operate with vertical, water-sprinkled evaporator plates and cyclic hot gas defrosting. The ice freezes on the vertical stainless steel evaporator plates to a thin layer, which keeps the thermal resistance always low. After a few minutes of ice formation is defrosted via automatic control for a few seconds with hot gas. In the case of the fall, the ice breaks up into roughly hand-sized pieces, which are separated from the water on a suction slide and then crushed in a rotating icebreaker. Later the crushed ice or chip ice falls down the full length of the Industrial Ice Machine and is available for transport with a conveyor belt or auger in the ice factory or industrial food processing.

Both the ice thickness and the piece sizes can be adjusted continuously. Our Industrial Chip Ice Machine gives you the maximum power reserve and safety in production. In addition, there are only a few moving parts, which increases operational reliability and minimizes maintenance. A crusher systems breaks the falling ice chips from the Industrial Ice Machine in adjustable ice chips with thickness in between 4mm to 12mm. Ice Storage systems can be adjusted.

Technical properties

Ice maker machine advantages

- Industrial ice maker machine with half the power consumption due to high evaporation temperatures

- Flake Ice Machine has no mechanical scraper as spare part

- Ice maker machine made entirely of stainless steel

- Ice making machine with Ideal ice temperature with -0.5 ° C, hardly undercooled

- Industrial ice making with no sharp flake ice edges

- Flake ice does not freeze during storage due to the high ice temperature -0.5 ° C

- Ice making machine with adjustable Flake Ice thickness and chip piece size

What are the Installation Requirements for Industrial Ice Making Equipment?

Technical specifications for the ice maker machine

- Industrial Ice quantities: 10 to 100 to / day Flake Ice

- Industrial ice making evaporator 100% stainless steel for ammonia and freons

- Industrial Ice Machine Plug-in units or for on-site refrigeration systems

Applications and benefits for an ice making machine

- Consumption ice for direct product cooling with ice making machines completely made of stainless steel

- Increasing the cooling effect through direct contact with ice

- Used in industries such like fish processing, meat processing, concrete cooling and pigment production and many more industries, in which chip ice is needed.

Ice making Machine constructions and dimensions

Typical dimensions

L (m) / B (m) / H (m)

Compact system: 2.5 / 0.8 / 2.3

System type A: 2.5 / 1.0 / 3.3

System type B: 2.5 / 2.5 / 3.3

without refrigeration system, with separator and ice crusher

Photos & examples